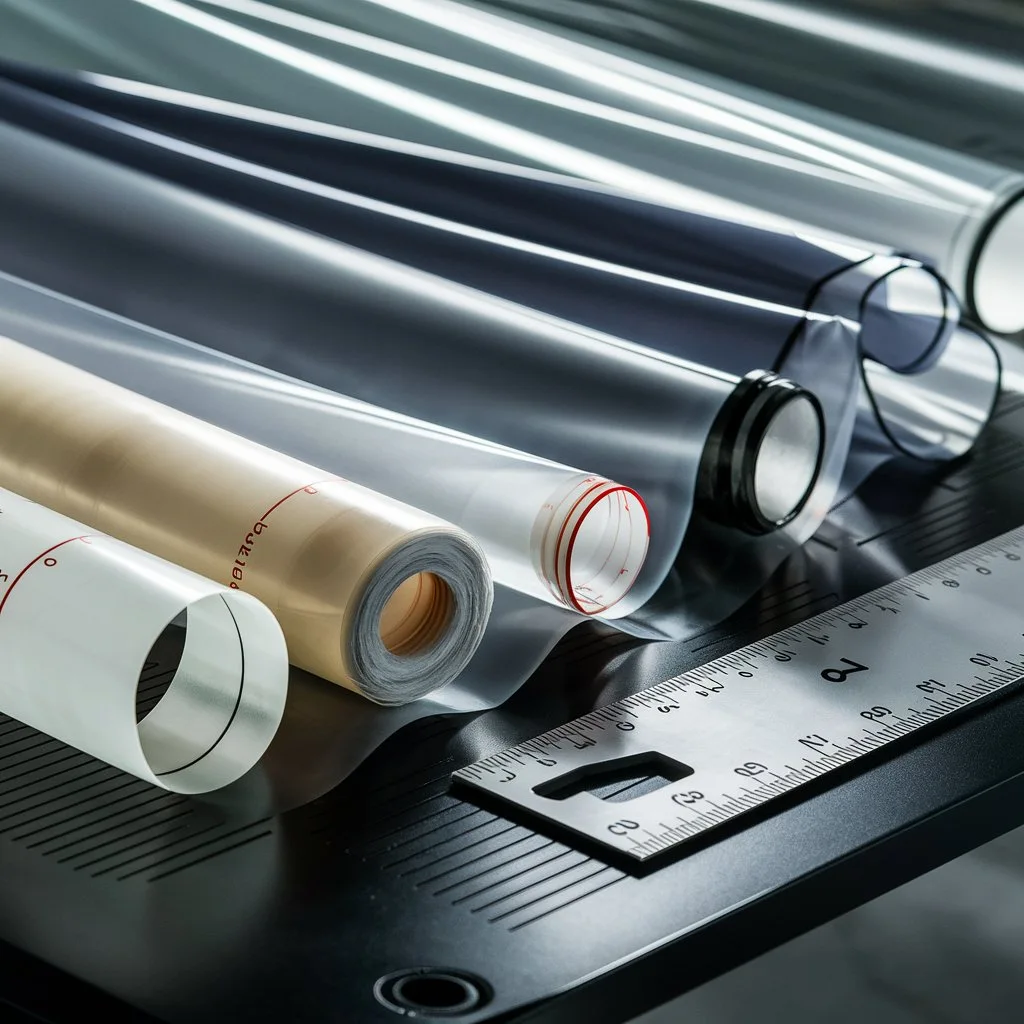

Types of industrial stretch: why should we know them? buying Industrial stretch is one of the vital tools in packing goods. This type of elastic-plastic is used in various industries due to its wide applications and many advantages.

In this article, we will examine what is industrial stretch? We provide various types of stretch and buy industrial stretch and introduce you to its different types and the uses of each one.

All kinds of industrial stretch🌟

Manual film stretch🖐️

Manual stretch film is a type of elastic-plastic used for the manual packaging of goods. This type of stretch is very suitable for small and medium-sized companies with a smaller packaging volume. You can pack your goods quickly and at the lowest cost using this stretch type.

Advantages and Disadvantages:

- Advantages:

Cheap and portable

Suitable for small packages

High flexibility

No need for special equipment

Disadvantages:

The need for more workforce

Less effective than machine stretch

The possibility of damage to goods in case of improper packaging

Manual stretch film is ideal for packaging goods that need to be moved quickly or stored in small spaces. Which of the Application of industrial stretch allows you to package your goods without the need for complex equipment and at the same time reduce your costs.

Machine film stretch 🤖

Machine stretch film is designed for packaging machines and is suitable for companies with high packaging volumes. This stretch allows you to pack your goods evenly and firmly using automatic machines.

Advantages and Disadvantages:

- Advantages:

high efficiency

Reducing the need for workforce

Uniform and tight packaging

High speed in packaging

Disadvantages:

High cost of equipment

The need for more space to install machinery

Need to train staff for proper use

Machine stretch film is ideal for companies that pack high volumes of goods. This stretch allows you to pack your goods at high speed and uniformly while reducing the need for a workforce.

Stretch film is pre-stretched⚙️

A pre-stretched stretch film is a stretch that is stretched to a specific size before use and is ready for packaging. This type of stretch allows you to pack your goods with minimal effort.

Advantages and Disadvantages:

- Advantages:

Reduce packaging time

Less need for workforce

Reducing the consumption of stretch film

Tighter and more uniform packaging

Disadvantages:

Higher cost than regular stretches

The need for special equipment for packaging

Pre-stretched film is suitable for companies that need fast and efficient packaging. The Property of industrial stretch allows you to pack your goods firmly and uniformly with minimal effort and in a short time..

Stretch thermal film🔥

Thermal stretch film is a stretch that uses heat to strengthen the packaging. This type of stretch is suitable for goods that need more protection and is used in various industries such as food and pharmaceutical industries.

Advantages and Disadvantages:

- Advantages:

Tighter packaging

More protection of goods

Suitable for products sensitive to impact and shock

Disadvantages:

Higher cost

The need for thermal equipment

More energy consumption

Thermal stretch film is ideal for goods that need extra protection. This stretch allows you to pack your goods more tightly and safely by using heat and prevent possible damage.

Essential points in choosing industrial stretch🧐

Thickness and stretch📏

Choosing the right thickness and tensile strength can help to achieve the best performance. For heavier goods, a thicker stretch is recommended. Also, the tensile strength of the stretch should be such that it can secure the goods well and prevent them from moving.

Type of raw material

Different raw materials are used to produce stretch, which hasdirectly affect the final quality. High-quality stretchers are usually made from high-quality raw materials. Choosing the suitable raw materials can help increase the durability and quality of packaging.

Compatibility with the environment🌍

Choosing environmentally friendly stretch marks and reducing negative environmental impacts can contribute to your company’s social responsibility. Using recyclable stretchers and reducing plastic consumption can help preserve the environment.

Methods of using industrial stretch🛠️

Manual methods

People wrap the film around the product using a stretcher in this method. This method is suitable for small packages. Using this method requires workforce and may take more time.

Machine methods⚙️

In this method, packaging machines wrap the stretch film uniformly and firmly around the product. This method is suitable for large packages and large volumes. Using packaging machines can reduce time and increase efficiency.

Safety tips⚠️

It is essential to use gloves and safety glasses to prevent possible damage during packaging. Also, ensuring that packaging machinery settings are correct and training employees properly can help reduce risks and increase safety.

Conclusion🏁

A summary of benefits and essential points📋

Various industrial stretch types can help improve efficiency and reduce packaging costs. Choosing the proper stretch for your business needs can make a big difference. Manual stretch film is suitable for small packages, and machine stretch film is ideal for large and high-volume packages.

Also, pre-stretched stretch film and thermal stretch film each have their advantages and applications.

Suggestions and recommendations💡

Please check your specific needs and consult relevant experts before choosing the proper stretch. Also, using eco-friendly stretchers can help preserve the environment and show your social responsibility.

Considering the types of industrial stretch and the important points in choosing and using them, you can help improve the packaging process and increase the efficiency and export of industrial stretch in your business. Choosing the right type of stretch and observing safety tips can help reduce costs and increase the quality of packaging.