Have you ever thought about how and with what materials the resistant and flexible plastics that we use in our daily lives are made?🤔

The raw materials of nylon are among the exciting chemical compounds that are used in many products, from clothing to food packaging.🛍️

In this article, we’ll explore the behind-the-scenes secrets of nylon’s raw materials and see how they go from raw materials to high-quality plastics. We’ll also show you how buying nylon plays a part in your everyday life and why it’s so popular. And it is widely used. 🌍✨

What are the raw materials of nylon?🧪

What is nylon? Nylon is one of the synthetic polymers that is made from certain chemical compounds. This substance was discovered and introduced to the market in the 1930s by the DuPont company. Nylon quickly found its place in various industries due to its unique properties, including high strength, flexibility and ability to withstand various conditions. 🌍✨

The main components of nylon🔬

Nylon is made from polyamides. Polyamides are a group of chemical compounds formed by the reaction between diamines and diacids. These compounds have long polymer chains that give nylon unique physical and chemical properties.

-

Polyamides: the basis of making nylon🧬

Polyamides are the main chemicals used in the manufacture of nylon. These materials are composed of carbon, hydrogen, oxygen and nitrogen and are converted into long-chain polymers by specific chemical reactions.

-

Other chemicals: Additives to improve properties☢️

In addition to polyamides, other chemicals are added to nylon to improve its properties. These additives can include anti-oxidation agents, softeners and heat-resistant agents.

How are nylon raw materials produced?🧬

Nylon is widely used in various industries due to its unique characteristics, such as high tensile and wear resistance. Also, the differences between nylon and nylex in their chemical composition and physical properties have made each of them to be considered in specific applications.

Nylon is commonly used in the production of fibers and fabrics, while Nylex is mainly used in the production of plastic bags and lighter packaging.

۱. Starting with raw materials🌱

First, materials such as carbon, hydrogen, oxygen, and nitrogen are used to make all kinds of nylons. These materials are combined and become polymers called nylon.

۲. Starting the polymerization process🧪

The raw materials go into a particular machine called a polymerization reactor. Here, the temperature and pressure are adjusted to the right amount so that the raw materials are converted into long polymers that form the properties of nylon.

۳. Choose the type of nylon

All nylons are similar in some way, but the demand for Mahsan Afrough may be different. For example, nylon six and nylon 6,6. Each of these has its properties, which are chosen according to the needs of Mahsan Afrough.

۴. Add extras🌟

To improve the properties of nylon, additives such as anti-oxidation agents or softeners can be added to it. These additives can help nylon to perform better and be more resistant.

۵. Sustainable production process🌍

I don’t know how many of our friends understand this; it is very complicated, but if it is done, it can help our environment a lot. Better nylon production processes can help reduce environmental problems.

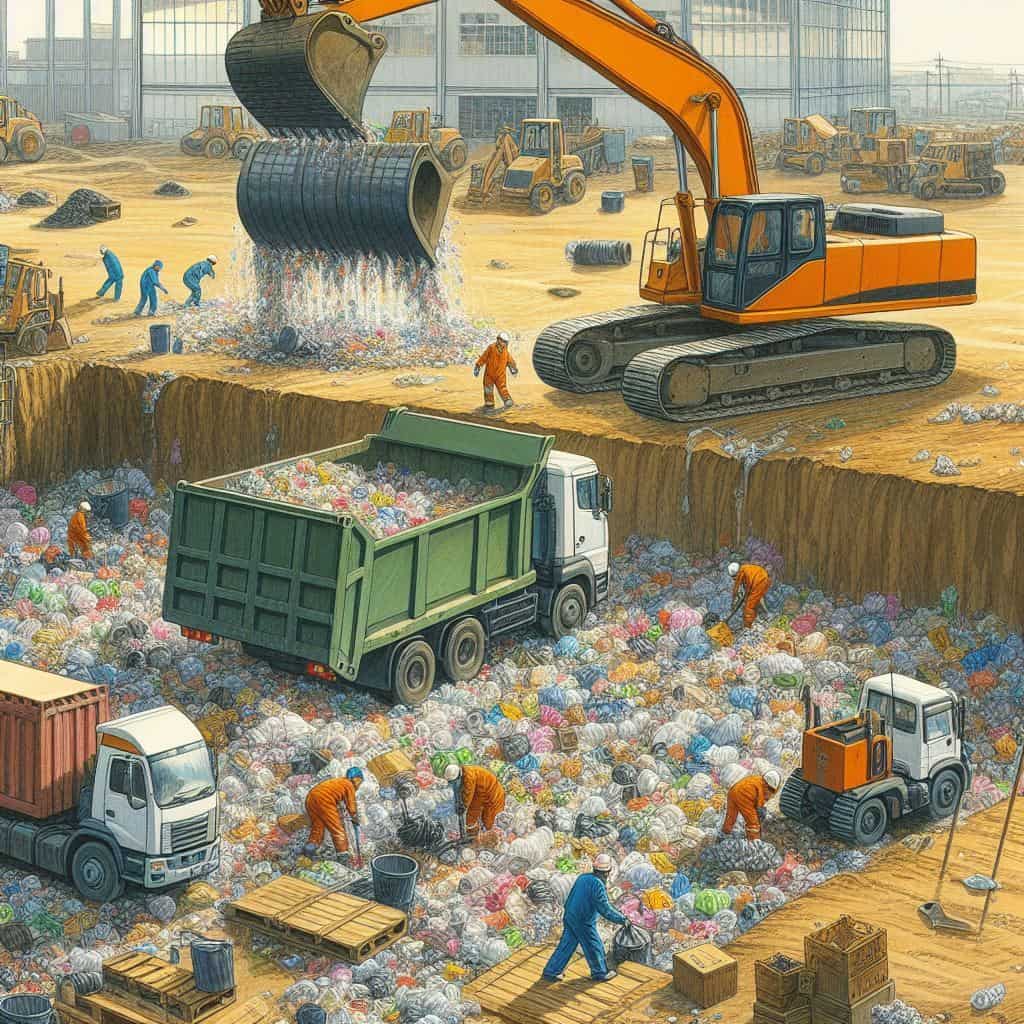

How to damage nature from nylon raw materials🌿

We all use nylons, but did you know that these materials can harm nature? Let’s see how you are!

۱. Indecomposability and tensile equations🛢️

Nylon is one of the non-degradable plastics; that is, it does not decompose quickly in nature. This makes them remain for long periods when they are released into the environment and gradually turn into smaller pieces that harm nature.

۲. Effects on animals🐟

Nylon pieces that are distributed in the environment as tiny plastics can harm different animals. These plastics may be mistakenly consumed or treated as food, which can lead to digestive problems or stomach blockages in animals.

۳. Pollution of water sources💧

Nylons that are spread into natural waters in the form of small plastics can harm the pollution of water resources and marine life. This problem can negatively affect the ecological balance and water ecosystems.

Solutions to reduce the adverse effects of nylon raw materials on nature

۱. Recycling♻️

Use the collection and recycling of used nylons to produce new products. This work can reduce the re-production of nylon and the consumption of natural resources and help preserve the environment.

۲. Reduce consumption🚫

Continued use of less polluting and environmentally friendly alternatives, such as products with paper or recyclable packaging, will help reduce nylon consumption.

۳. Waste management🗑️

It is necessary to improve the management and correct disposal of nylons to prevent them from entering the environment. Using appropriate recycling and disposal systems can reduce their adverse effects.

Characteristics of nylon raw materials

۱. High resistance to wear and corrosion🛡️

Due to its resistant polymer structure, nylon is very suitable for parts that require physical and mechanical resistance.

۲. Flexibility and diverse application🔄

This material can easily be used in the production of clothes, bags, shoes, car parts, and packaging.

۳. Resistance to thermal and chemical conditions🌡️

Nylon can withstand different temperatures and chemicals, which is very vital for many industries.

۴. Lightness and low weight⚖️

The light weight of nylon makes it a suitable option for nylon export and packaging in parts that require lightweight.

۵. Ability to recycle♻️

The recyclability of nylon helps reduce the use of natural resources and reduce the environmental impact associated with the production of new materials.

Conclusion💚

By observing these simple things, we can help preserve nature and reduce the negative impact of nylon raw materials on the environment. We can all help maintain the beauty of nature by making intelligent and responsible choices.