Nylon raw materials: materials that give meaning to everyday life!

Nylon raw materials raw materials for making nylon include hexamethylene diamine, adipic acid, hexamethylene diamine, adipic acid, and ammonium carbonate. These materials are linked together in the polymerization process to form long, polymer chains that form the final nylon.

Nylon is used in a variety of industries including apparel, packaging, automotive, and food due to its properties such as scratch resistance, elasticity, and lightweight.

Also, nylon has its attractions from an environmental point of view, because it can be recycled and is used as an alternative to materials such as single-use plastics.

Nylon raw materials consist of two main groups: amine materials and acidic materials.

Among the amine substances, hexamethylene diamine is liquid and colorless. This substance consists of two carbon atoms, one nitrogen atom, and six hydrogen atoms. On the other hand, acidic substances include adipic acid. This acid has two carboxylic acid groups and is used as a key acid material to produce nylon.

When these two groups of substances react with each other, a process called polymerization occurs. In this process, the monomer units are linked together to form long polymer chains that makeup nylon.

Finally, after the polymerization process, nylon is produced as a polymer with suitable mechanical and physical properties, which is used in various industries such as clothing, packaging, automotive industries, etc.

What are amino substances?

Amine substances are a group of chemical compounds that contain an amine group (-NH2). Amines are chemically divided into two categories: organic amines and aromatic amines.

Organic amines: This category includes amines in which the nitrogen atom is attached to one or more carbon atoms. Some of the well-known organic amines include amines, amides, secondary amines, and tertiary amines.

Aminates are derivatives of organic amines that contain the NH2 group, for example, methylamine (CH3NH2). Amides are compounds in which the NH2 group is attached to a carboxyl atom, such as amino acids.

Aromatic amines: These amines contain an amine group attached to an aromatic ring such as benzene. An example of an aromatic amine is aniline (C6H5NH2), which consists of a benzene ring and an amine group.

Amines are used in various industries such as chemistry, pharmaceuticals, agriculture, and food industries. For example, amines are used in the manufacture of drugs as the main molecules and also in the production of polymers and dyes as catalysts or the main material

What are acidic substances?

Acidic substances are a group of chemical compounds that chemically have an acidic group (-COOH). This group consists of one carbon atom that is connected to two oxygen atoms and one hydrogen atom.

Acidic substances can be diverse in terms of structure and properties, and in this sense, they may be divided into two categories: organic acids and inorganic acids.

Organic acids: This group includes acids that have carbon-hydrogen bonds. These acids are usually derived from organic compounds and may be found in nature or produced synthetically.

Some of the most famous organic acids include acetic acid, formic acid, acetic acid, and lactic acid.

Mineral acids: These acids are usually derived from mineral compounds and are usually found in nature. Some of the most famous mineral acids include sulfuric acid, hydrochloric acid, and nitric acid.

Acidic substances are used in many chemical industries and processes, including fertilizer production, pharmaceutical industries, plastic manufacturing processes, and battery production. Also, these acids are used in the food industry as food additives, in adjusting the pH of products, and in food production processes

How are nylon raw materials produced?!

۱. Preparation of raw materials:

Amine substances: This includes compounds such as hexamethylenediamine, which is obtained from the production process of ammonia and hexamine.

Acidic substances: Adipic acid is produced from the process of hydroxylation.

۲. Polymerization process:

In this step, amino and acidic materials react together to produce nylon polymer chains. This reaction is known as polymerization and is done under the right pressure and temperature.

In this process, the carboxylic group of the acidic substance reacts with the amino group of the amine substance and binds together.

۳. Forming process:

In this step, nylon is produced as a polymer in the form of liquid or solid granules. This nylon can be used as raw materials for use in various industries such as clothing, packaging, and automotive industries.

In general, the production process of nylon starts from amino and acidic materials and continues with the polymerization process in which the monomer units are linked together. Then the produced nylon polymers can be used as raw materials in various industries.

Do nylon raw materials harm nature?

Raw materials used in the production of nylon, such as hexamethylene diamine and adipic acid, do not normally harm nature under normal conditions. These materials are chemically produced and used in the nylon production process.

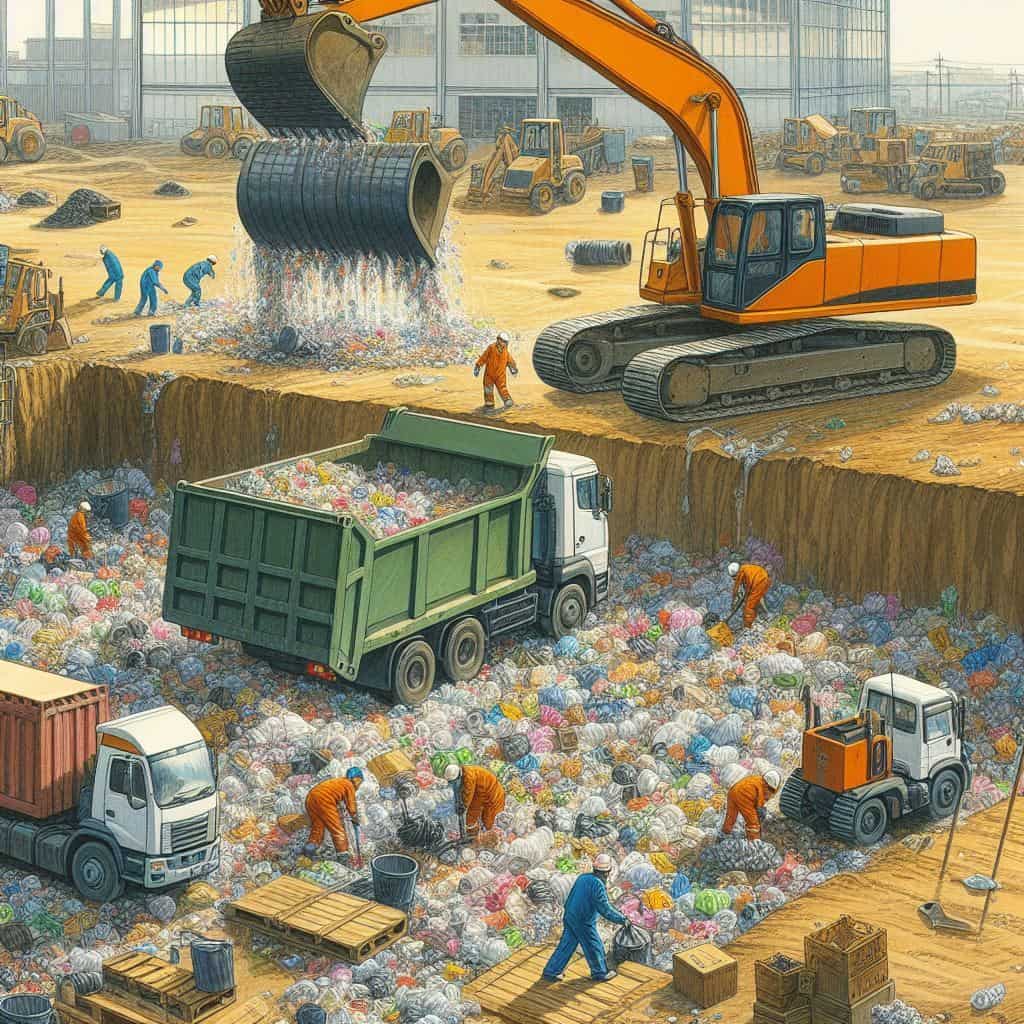

However, it is important to deal with the environmental sustainability of these materials. Nylon raw materials, when not disposed of properly or released into the environment in impurity, may harm the environment

For example, if nylon is not degraded as waste or waste and released into the seas or desert soils, it can be dangerous to animals and other living organisms.

These substances can be non-biodegradable or become toxic substances that can harm a wide range of organisms in the soil and groundwater.

Therefore, it is important that when using nylon or other polymeric materials, proper disposal and recycling methods are used to reduce negative effects on the environment. Using recycling technologies and reducing the consumption of non-degradable materials can help preserve the environment.

Characteristics of nylon raw materials

Raw materials used in nylon production, such as hexamethylene diamine and adipic acid, have important properties that have a significant effect on the final properties of nylon. Some of these features include:

High mechanical strength: As a polymer, nylon has high tensile and impact resistance, which makes it suitable for use in applications such as apparel and automotive parts.

Abrasion and abrasion resistance: Nylon has good abrasion and abrasion resistance, which makes it suitable for use in applications such as packaging and mechanical parts manufacturing.

Resistance to moisture and breakage: Nylon has good resistance to moisture and other environmental influences, and it also has good flexibility that prevents it from breaking.

Chemical resistance: Nylon is resistant to chemical effects such as acids, bases, and other chemicals, which are used for applications such as chemical industry and food packaging.

Heat resistance: Nylon has good heat resistance, which is used for applications such as manufacturing parts at high temperatures.

In general, nylon raw materials as synthetic polymers have unique characteristics that make them one of the most widely used and popular materials in various industries.

Disadvantages of nylon raw materials

Although the raw materials used in the production of nylon have useful properties, there are also some disadvantages. The main disadvantages of nylon raw materials are:

Environmental effects: Nylon production requires a lot of energy consumption, which may lead to an increase in greenhouse gas emissions and air pollution. Also, nylon wastes, especially if they are disposed of incorrectly, may harm the environment.

Heat sensitivity: Some types of nylon may be more heat sensitive and deform or melt unintentionally at high temperatures.

Relative Corrosion Resistance: Compared to some other polymers, nylon may be less resistant to corrosion and in some cases may require a coating or protective coating.

However, with the improvement of production processes and the use of recycling technologies, many of these disadvantages can be reduced and the use of nylon becomes a more environmentally friendly approach.