Imagine you are walking down the street on a rainy day and you need to buy some small items. You enter a store and the seller gives you two options for packing your purchases: a nylon and a nylon. Now the question arises, what is the difference between nylon and nylex?🌧️🛍️.

Why is the difference between nylon and nylex important?🤔

You may ask, why should we know the difference between nylon and nylex? The answer is simple: each of these materials has its own uses and characteristics, and understanding them can help you make better choices in your daily purchases and uses.

What is nylon?

History and introduction of nylon🧵

What is nylon? Nylon was first produced by DuPont in 1935 and quickly replaced many natural fibers. This synthetic polymer was used in various industries due to its high resistance and long-term durability.

Features of nylon🌟

Nylon has high resistance to tension and heat. Also, due to the characteristics of nylon, which makes it ideal for the production of clothes, socks and industrial parts.

What is Nylex?

Introduction and history of Nylex📜

Nylex is made from linear light polyethylene (LLDPE) or high-density polyethylene (HDPE). This material is vital in the production of disposable plastic bags due to its transparency and tear resistance.

Features of Nylex🔍

Nylex is more brittle than nylon but has good puncture resistance. It also has high gloss and transparency, which makes it suitable for food packaging.

Critical differences between Nylon and Nylex🔍

Raw materials and chemical composition🧪

Nylon raw materials are different from Nylex. Nylons are made from polyamides, which have polymer chains with nitrogen linkages. This allows nylon to be robust, flexible and wear-resistant.

In contrast, Nylex is made from polyethylene, which is a simpler polymer with chains linked by carbon groups. This makes Nylex more brittle but highly tear-resistant.

Physical and mechanical properties⚙️

Due to the polyamide structure, all types of nylons are more resistant and have higher flexibility to tensile and compressive forces. These properties make it a popular choice for compact garments and industrial components.

In contrast, Nylex is more fragile due to its polyethylene structure but has high tear resistance, making it suitable for single-use plastic bags and packaging.

Applications and uses🛠️

Due to its resistance and flexibility, plastic is mainly used in various industries such as clothing, carpets, industrial parts and sports tools. For example, in underwear, running bags and various engine parts.

On the other hand, because of its cheapness and tear resistance, Nylex is mainly used in food packaging, disposable plastic bags, and the like.

Price and economy💰

Nylex has a lower production cost due to the use of polyethylene and simpler production processes, which directly leads to cheaper Nylex products.

On the other hand, nylon has a higher price due to more expensive raw materials and more complicated production processes, which is suitable as an alternative for items that require high resistance.

Advantages and disadvantages of nylon and nylex⚖️

Advantages of nylon✅

Nylon, as a polymer material, has many characteristics, including high resistance to tension and pressure, which makes it an ideal option for use in industrial parts, compressed clothes and durable products.

Additionally, nylon has a long shelf life, which limits it as a recyclable material.

Disadvantages of nylon❌

Disadvantages of nylon include higher cost than other materials, especially compared to nylon, and less recyclability. The nylon recycling process is usually more complicated and requires unique processes that can be more costly and time-consuming.

Benefits of Nylex✅

Nylex is more affordable due to the use of polyethylene, making it an economical option for food packaging, single-use plastic bags and similar products. Also, Nylex has high transparency, which is helpful for packaging all kinds of materials.

Disadvantages of Nylex❌

One of the disadvantages of Nylex is its fragility, which may cause limitations in some applications. Also, Nylex is less durable than nylon due to the more straightforward structure of polyethylene and its properties.

Environmental tips🌿

Both substances have environmental effects. Nylon has a longer lifespan due to its more excellent durability but is more difficult to recycle.

Nylex generates more waste due to single use. Conscious choice and responsible consumption can help reduce negative impacts on the environment.

Similarities of Nylon and Nylex🔄

Being a polymer🔬

Both nylon and nylon are made from unique chemical compounds that involve the reaction between the amine and carboxylic groups in the hexamethylenediamine and adipic acid molecules. These combinations give them unique properties.

Physical resistance💪

Both materials have high physical resistance. They are highly tensile and compressive and are usually resistant to wear and tear. These features make Nylon and Nylex suitable for many industrial and household applications.

Heat resistance🔥

Both materials have good heat resistance, but Nylex is usually more heat resistant due to its unique composition and manufacturing processes. This feature is handy in industries that require high thermal resistance.

Corrosion resistance⚙️

Nylon and Nylex both have good corrosion resistance. However, Nylex may be more resistant to corrosion due to special additives and manufacturing processes. This feature is essential for long-term applications in corrosive environments.

Wide applications🏭

Nylon and Nylex are used in various industries. This includes clothing, construction, electronics, medicine, and many other industries. For example, they are used in sportswear, electronic tools and even medical equipment.

Export of nylon and nylex🌍

The export of nylon and nylex has flourished in the world markets due to the unique characteristics of these materials. Nylon is used in various industries such as clothing, packaging and industrial parts due to its high resistance to tension and heat and suitable flexibility. Because of its lightness and tear resistance, Nylex is mainly used in the production of plastic bags and light packaging.

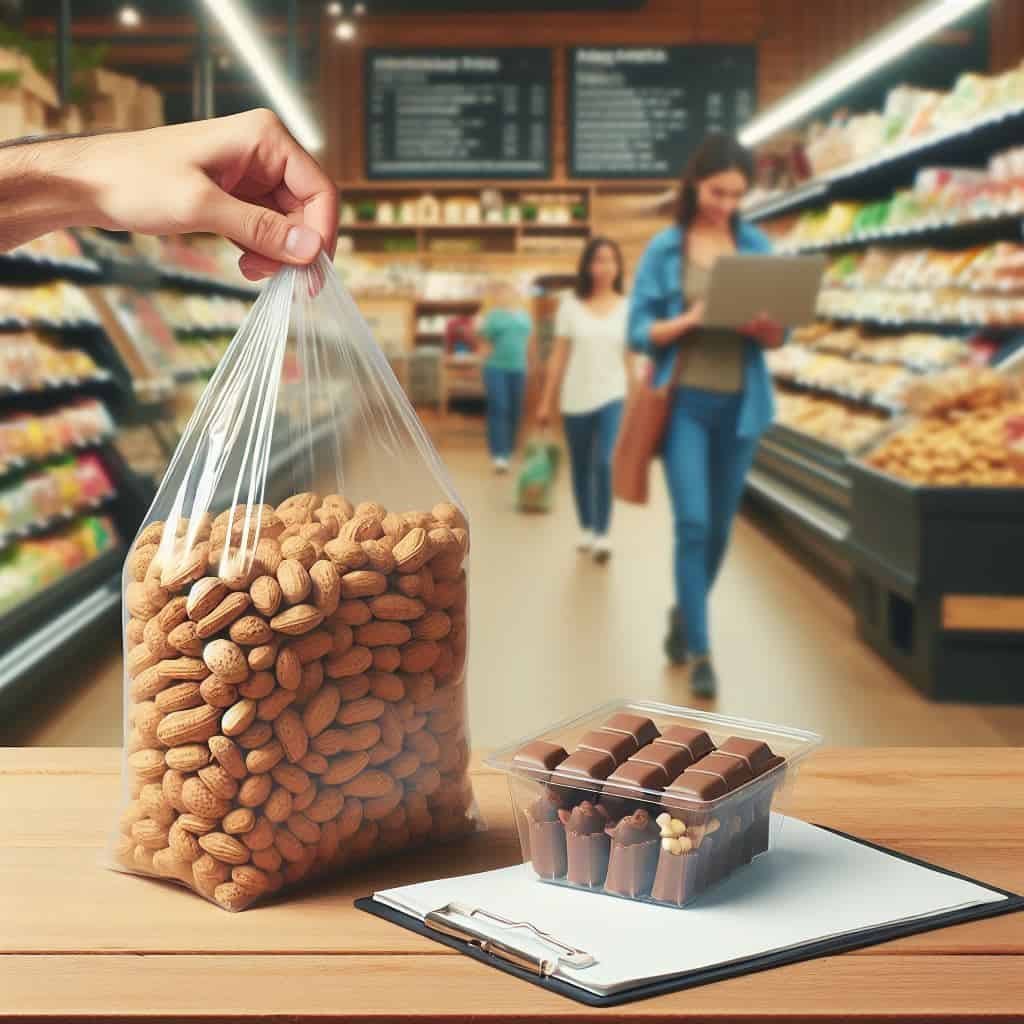

Nylon and Nylex in the packaging industry📦

Nylon and Nylex are both used as packaging materials in various industries, but due to their unique properties, there may be differences in applications and types of packaging. In the following, we mention some of the uses of nylon and nylon in the packaging industry:

Nylon:

Coating: Nylon is used as a transparent packaging material with wear and tear-resistant properties to cover products such as food, electronic products, medical devices, etc. These features help to gain consumer trust in the product and maintain it properly.

Packaging film: Nylon is used as a formable packaging material in the production of packaging films for food, electronic products, health products, etc.

Both Nylon and Nylex are used to package fresh products such as meat, fish, fruits and vegetables as a protective layer that can prevent freshness and delay the spoilage process.

Nylex:

In general, both nylon and nylon are used in the packaging industry as packaging materials with unique properties that contribute to the safety, maintenance, and longevity of products. The use of each of these packaging materials depends on the needs and properties of the products.

Nylon and Nylex in the food and pharmaceutical industries💊

Grouping of food products🍱

Due to its high resistance to moisture, Nylex is used to package food products such as meat, fish, chicken, and various types of cheese.

These features allow the product to be kept for a long time in conditions of freshness and proper quality.

Pharmaceutical packaging💉

Nylex is used as a packaging material with gas-resistance properties for packaging drugs and medical materials. These features help ensure the safety and quality of pharmaceutical products.

In general, both are used in the packaging industry as packaging materials with diverse properties, the choice between which depends on the type of product, packaging needs, and expected properties.

Nylon and Nylex are used as packaging materials; the difference between Nylon and Nylex is the use of different products in these two materials.

Which one is more suitable for you?🎯

Choosing between nylon and nylon depends on your needs. If you are looking for durability and strength, nylon is a better option. But if you are looking for an economical solution for disposables, Nylex is more suitable.